QUALITY CONTROL

Quality Control and Fabric Testing

Eysan Fabrics control the quality to meet all the fabric testings requirements. We can also send the fabrics to 3rd party laboratory for testings if required.

Quality Control

Eysan Fabrics is committed to providing functional fabrics with stable quality, hence the quality control and in-house fabric testings are both crucial because fabric science is a complicated subject. Any adjustment during production could change the outcome of fabrics. That’s why we take quality control seriously.

We have two QC personals with two assistants in house in charge of monitoring every detail of production.

From the beginning of the production, every detail of production, which could affect the result, would be recorded. Every item has a traceable production record. Each of the production resumes would be digitized in our ERP system.

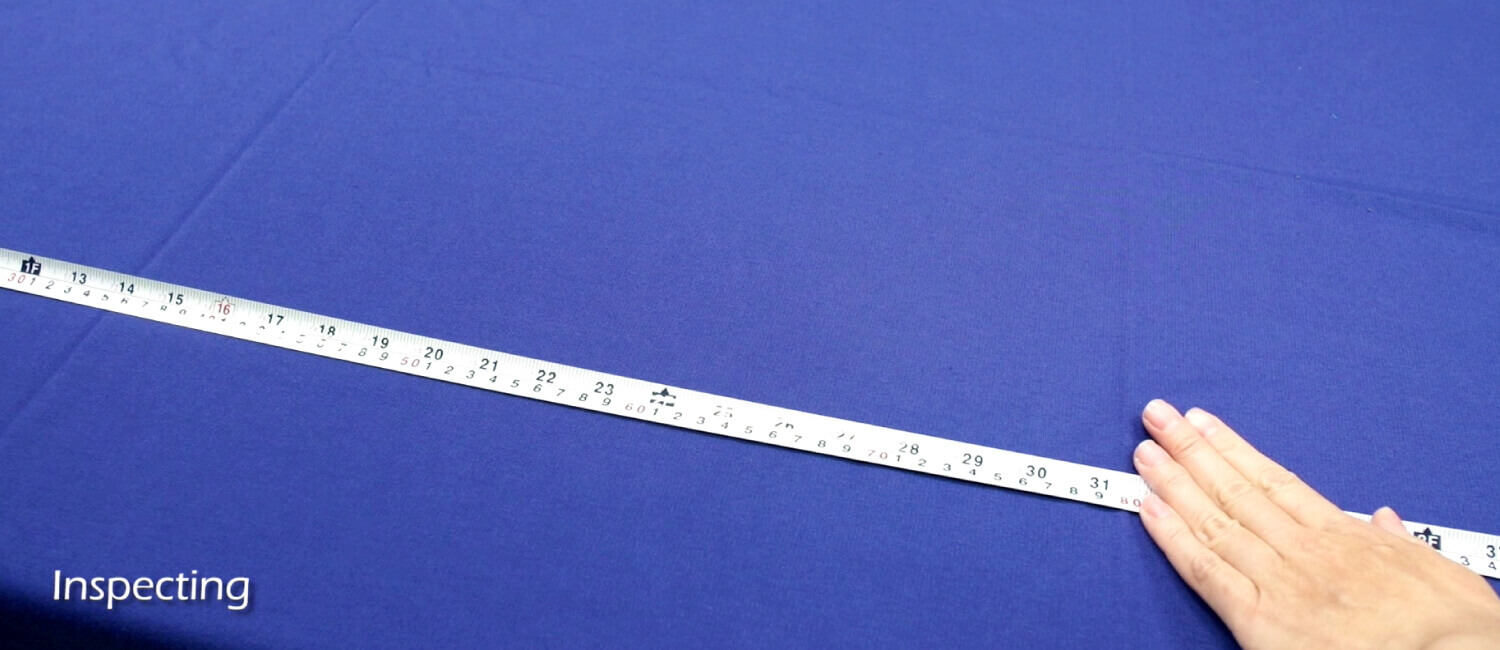

We have two more quality control supervisors stationed in production lines to monitor the quality. The fabrics are inspected internally Our fabrics are all inspected in 3rd party inspection factory before dispatching.

Fabric Testing Requirements

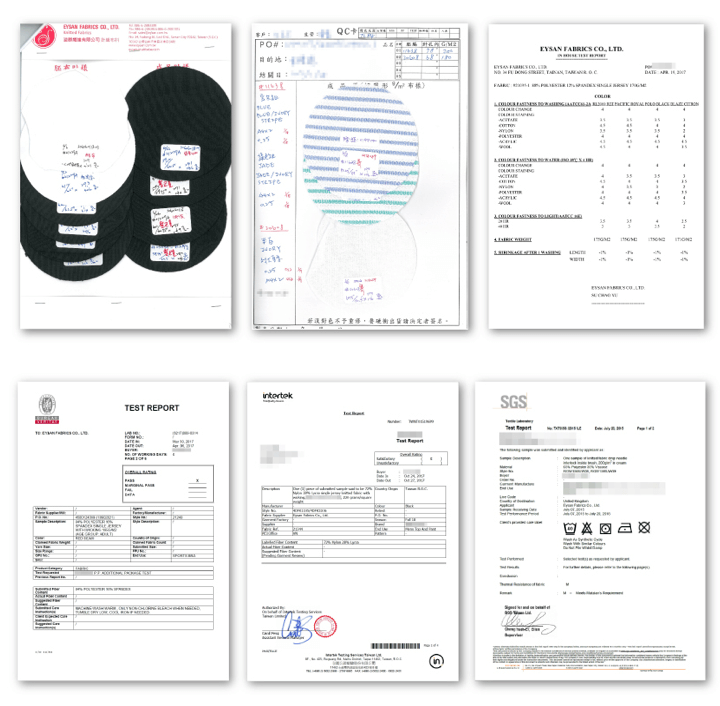

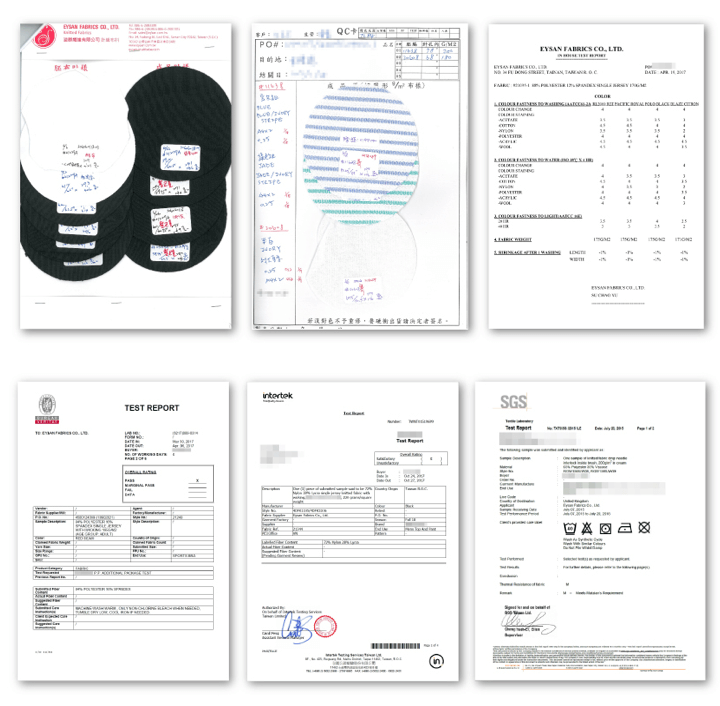

In order to ensure the quality, we do in-house physical testing, including, fabric weight, fabric width, shrinkage, skewness color fastness to washing and color fastness to water.

If required, fabrics could also be tested in a third-party testing labor, for example, BV, SGS or Intertek.

Quality Control

EYSAN is committed to provide functional fabrics with stable quality, hence the quality control and in-house fabric testings are both crucial, because fabric science is a complicated subject. Any adjustment during production could change the out come of fabrics. That’s why we take quality control seriously.

We have two QC personals with two assistants in house incharge of monitoring every details of production.

From the beginning of the production, every details of production, which could affect the result, would be recorded. Every item has a traceable production record. Each of the production resume would be digitized in our ERP system.

We have two more quality control supervisors stationed in production lines to monitor the quality. The fabrics are inspected internally Our fabrics are all inspected in a 3rd party inspection factory before dispatching.

Fabric Testing Requirements

In order to ensure the quality, we do inhouse physical testing, including, fabric weight, fabric width, shrinkage, skewness color fastness to washing and color fastness to water.

If required, fabrics could also be tested in a third party testing labor, for example, BV, SGS or Intertek.

Let’s us help you!